Bucket Elevator

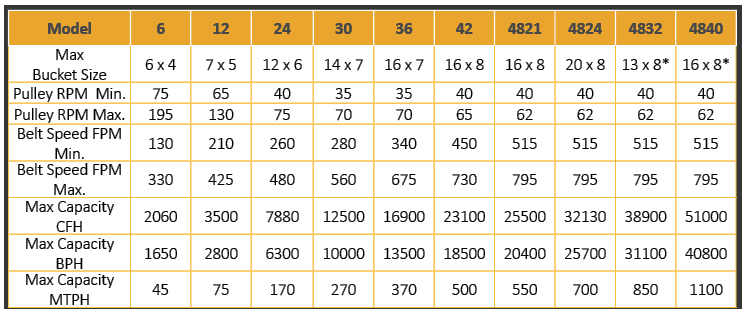

HEAD SECTIONS

Heads are designed clean centrifugal discharge including:

• Heavy duty Crown faced double disc drum pulley with vulcanized rubber or replaceable slide lagging

• Heavy duty pillow block bearing, roller or ball style

• Adjustable bearing pedestals for simple belt tracking

• Inspection doors with heavy duty hinges and clamps, weather tight

• Engineered and machined steel shafts

• Adjustable discharge baffle plate

• Heavy duty construction with standard replaceable abrasion resistant steel, urethane, ceramic or any material based on customer specification

• Split hood with shaft seals

• Pressure relief door in hood with directional safety guard

• Bolt-on catcher bar assembly with removable bars for simple replacement – optional

DRIVES

• Standard Dodge shaft mount with belt drives on smaller sizes or SEW for larger sizes.

• Alternate drive models available based on customer specifications

• Shaft mount with belt drive

• Alternate shaft combinations are available based on customer specifications or applications

• OSHA guards

INLETS

• Standard raised box style inlet

• Alternate metered inlet or bypass style inlet available to suit any customer application

BELT & BUCKETS

• Heavy duty supreme oil resistant (S.O.R.) rubber belt engineered to suit the correct requirements for the application.

• All buckets based on the application and customer preference.

• All hardware options are available per customer specifications

STANDARD FINISH OPTIONS

• Powder coating

• Wet/polyurethane paint

• Stainless steel

• Galvanized

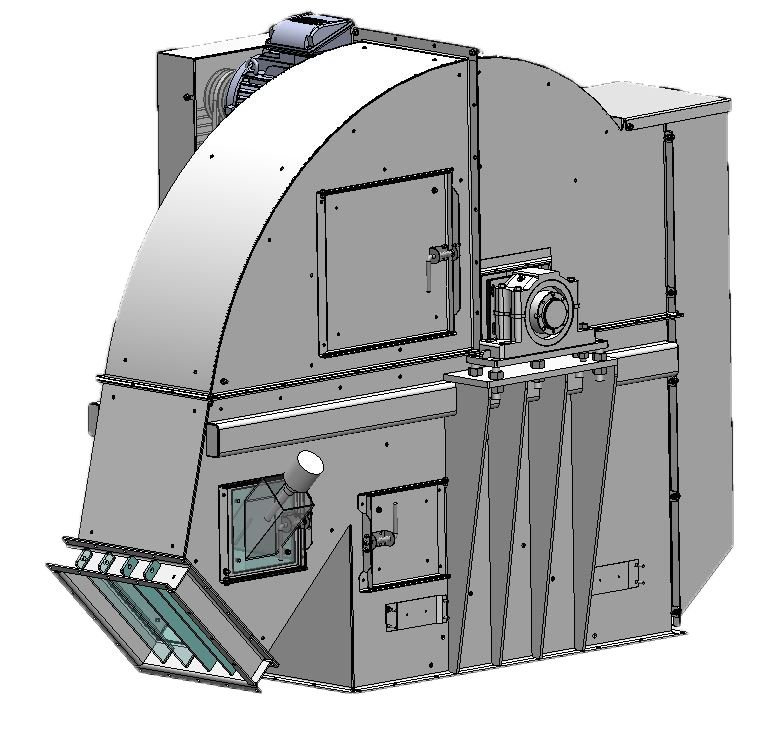

BOOT SECTION

• Heavy duty Crown faced double disc drum pulley

• Heavy duty reinforced bolted construction provides a strong foundation.

• External flange or pillow block bearings

• Heavy duty threaded rod for screw take-up.

• Gravity take-up available based on project application

• Inspection doors with heavy duty hinges and clamps, weather tight

• Bolted assembly

• Comes with one Standard boot inlet

• Liners are available to suit your specifications and application

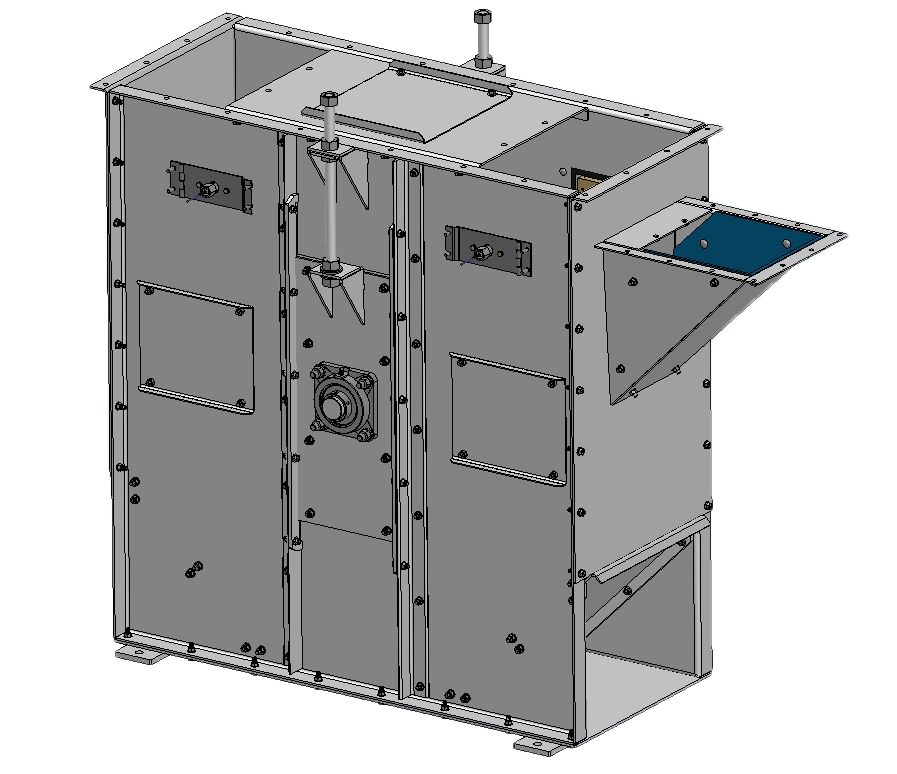

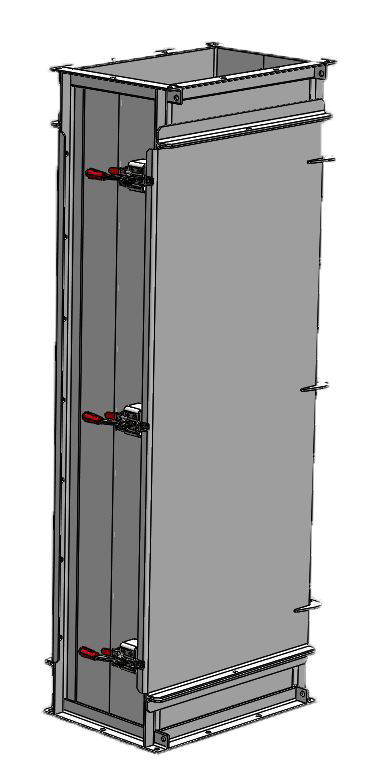

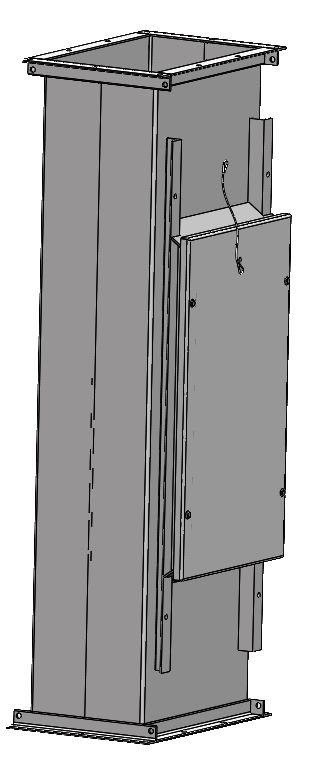

LEG TRUNKING

• Fully seal welded on a laser aligned jig to ensure strength and resistance to weather conditions

• Standard Heavy duty construction

• Standard 10’ -0” trunking sections

• Structural angle iron end flanges, Horizontal tie angles and cross bracing

• Heavy duty inspection trunking with large service and maintenance doors front and back

STANDARD MAINTENANCE ACCESS OPTIONS

• Ladders and safety cages

• Head Service platforms

• Distributor platforms

• Step off and rest platforms

Safety and Monitoring sensors are available to suit your specifications and application

Note: all bucket elevator venting is designed to NFPA 61 and 68