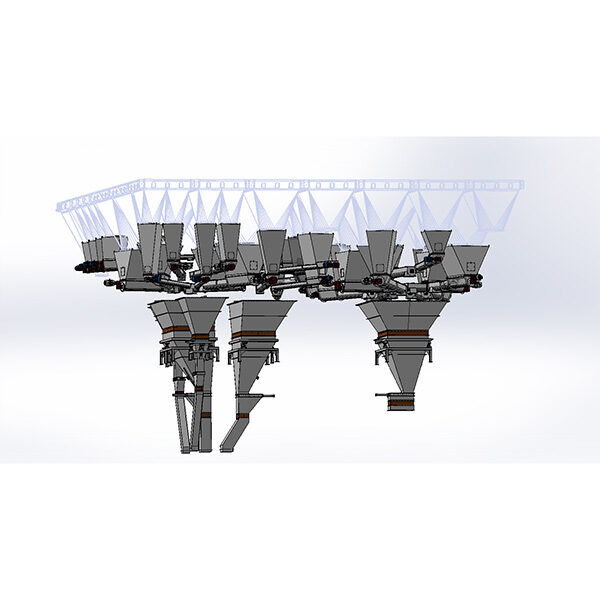

Design

The INDXAG Engineering & Design team is capable of designing site layouts for our customers from concept to final design. We have the expertise to design custom equipment such as CEMA screw conveyors, gates, valves, weigh hoppers, transitions, catwalks, platforms and various other custom equipment or components required to complete the installation.

Project Management

Our team has many years of project management experience that allows us to help our customers from concept through design, procurement, manufacturing, installation and commissioning of new installations. We aim to provide a complete solution for our customers.

Site Installations

Our very capable team of millwrights assemble and install equipment, do onsite mobile welding and fabrication, and provide quality workmanship so that our customers get a complete and high-quality final product.

Manufacturing

With our in-house laser cutting, forming, machining and welding capabilities we can manufacture equipment from stainless steel, aluminium, mild steel, Hardox, galvanized sheet and various other materials.

We offer various surface finish capabilities including powder coating, wet paint, hot dip galvanizing and pre-galvanized sheet to suit our customer needs.

Our manufacturing is based in Portage La Prairie Manitoba. Our highly skilled workforce can offer a diversified selection of quality metal fabrication services including:

- Mig, Tig and Stick Welding

- Brake press forming

- Laser Cutting

- Plasma Cutting

- Mill and Lathe machining