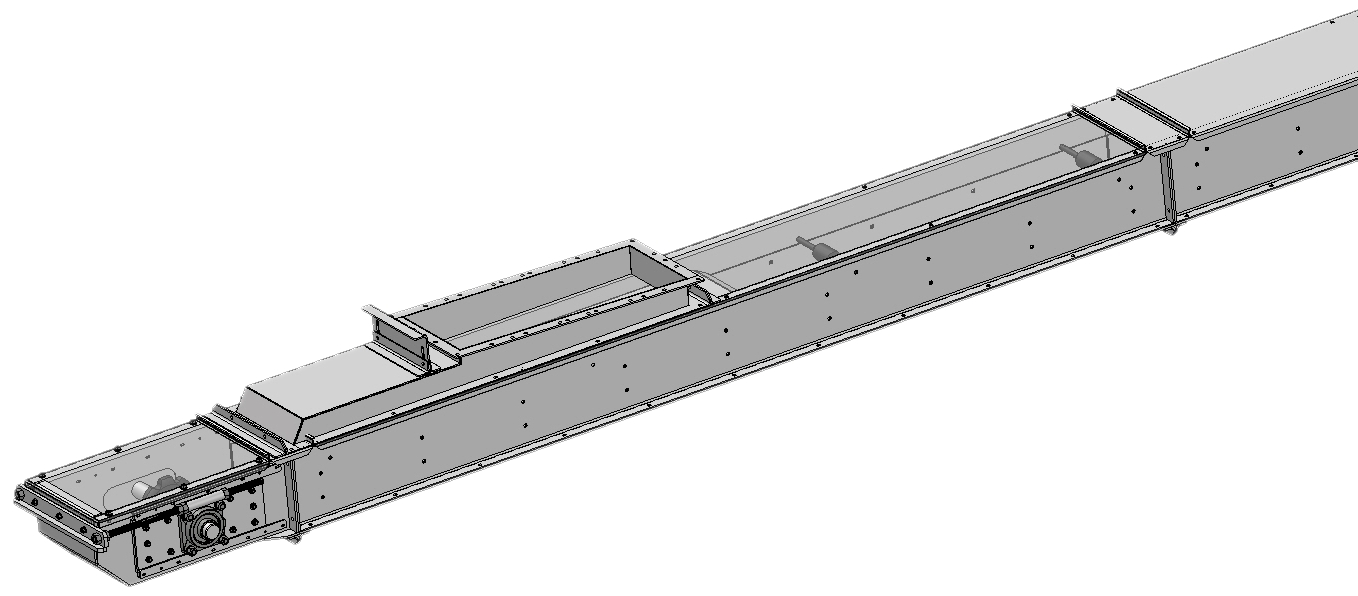

Drag Conveyor

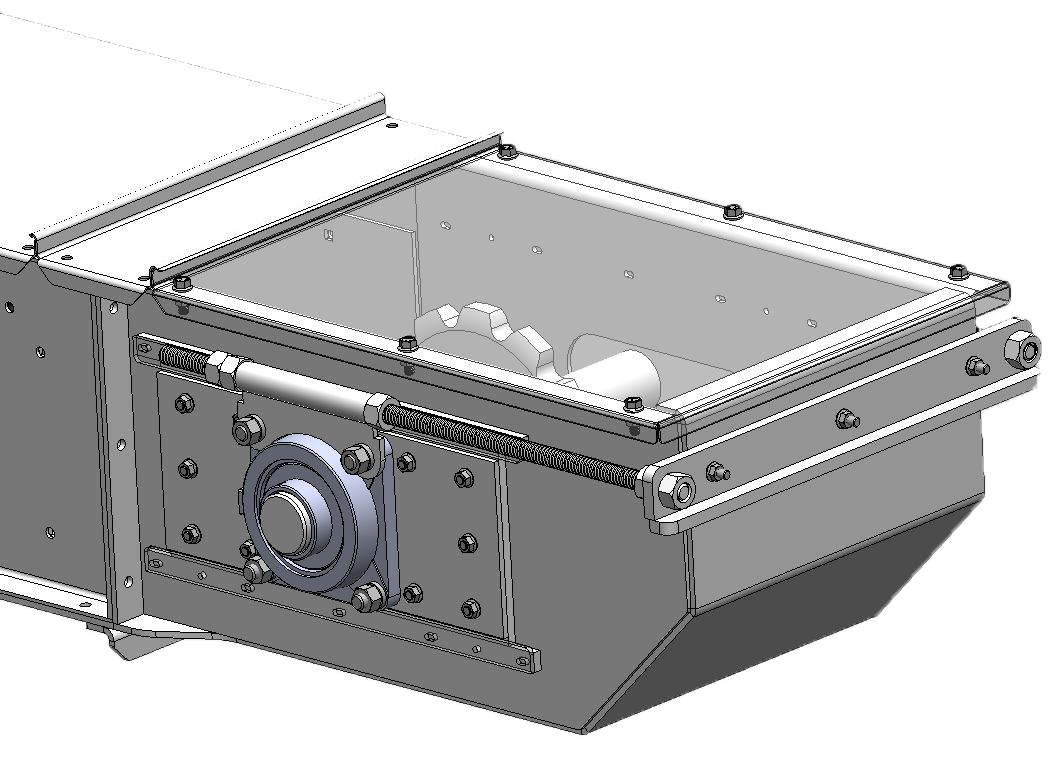

HEAD SECTIONS

• Available in standard box discharge or split style for HD applications for access and ease of maintenance

• Standard heavy gauge fully bolted assemblies

• Standard hardened tooth split sprockets on all conveyors

• Pillow block bearings

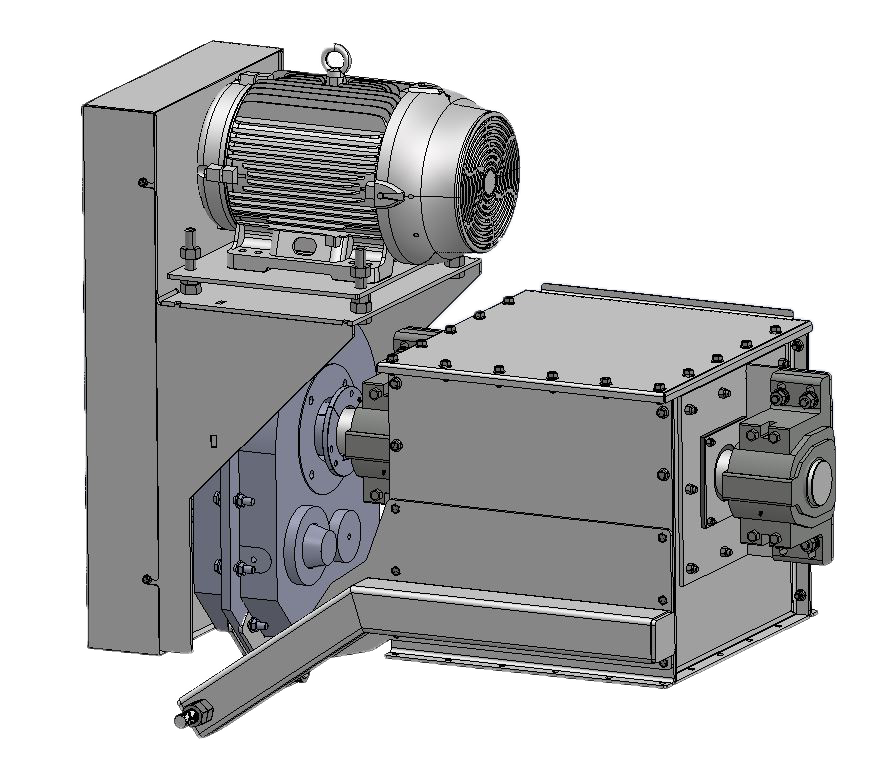

DRIVES

• Standard Dodge shaft mount with belt drives on smaller sizes or SEW for larger sizes.

• Alternate drive models available based on customer specifications

• Shaft mount with belt drive

• Alternate shaft combinations available based on customer specifications or applications

• OSHA guard

INLETS

• Standard raised box style inlet

• Alternate metered inlet or bypass style inlet available to suit any customer application

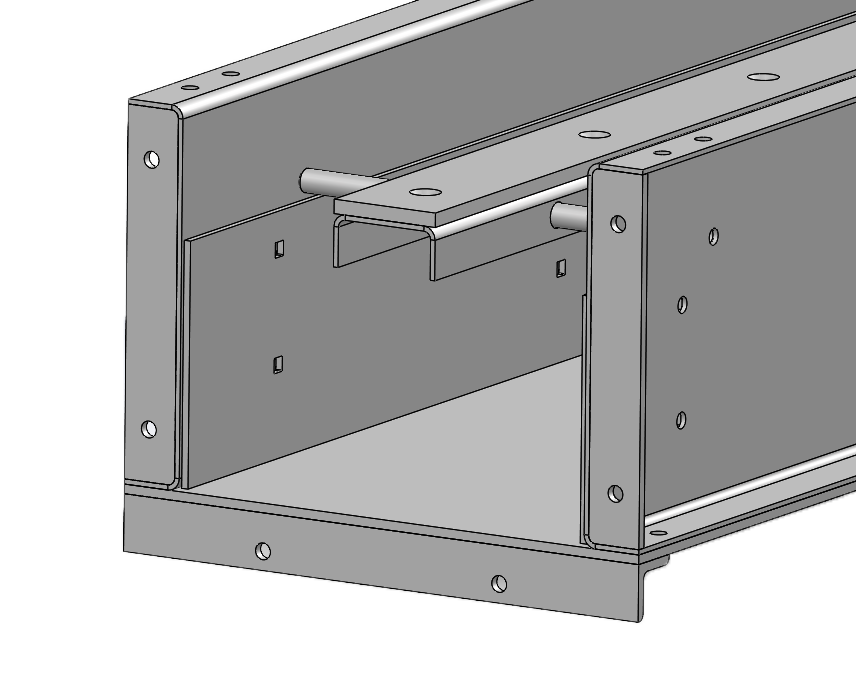

CHAIN

• All conveyor chain comes with HD steel flighting and UHMW bolted paddles specific to the applications

• Discharge Gates available in standard Inline, Cross or Flush styles

• Operator options: Manual, Electric Linear Actuator or gear motor, Hydraulic or Pneumatic

• Gates designed to be mounted for intermediate discharge or head end discharge.

COVERS

• Bolted – Environmental or weather-tight covers on head, tail trough sections

• Custom covers available based on customer specifications or applications

• Hinged and clamped options available upon request

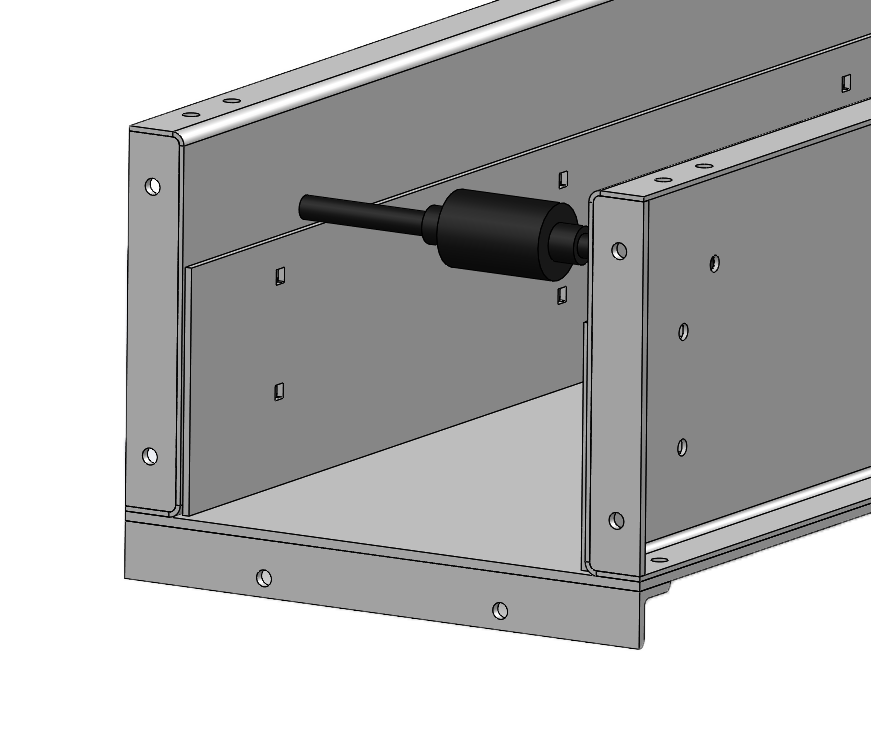

TAIL SECTIONS

• Available in standard Box or Split style for HD applications for access and ease of maintenance

• Standard heavy gauge fully bolted assemblies

• Standard Hardened tooth Split Sprockets on all conveyors

• Pillow block or take up bearing for split tails

TROUGH SECTIONS

• Bolted trough sections come standard with HD steel gauges specific to the application and conveyor size

• All trough come with HD A.R. steel side liners. Alternate materials and gauges are available based on customer specifications and applications

• All side panels and bottom plates are welded on a jig with HD flanges